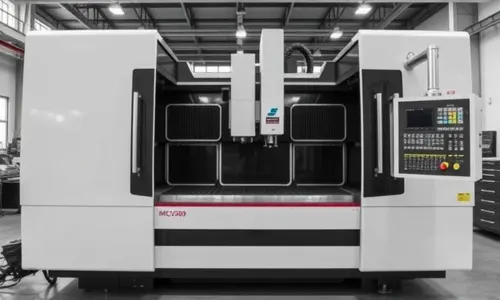

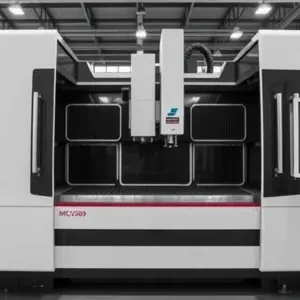

MCV300

Efficient and Space-Saving Machining Center for Small Components

This high-efficiency, compact machining center is specially designed for precision machining of small components, ideal for parts within a 300 mm cubic envelope. Its space-saving footprint makes it well-suited for modern production facilities with limited floor space.

Key features include:

- BT-40 Spindle Taper for reliable performance across various materials

- 12-Tool Automatic Tool Changer (ATC): Equipped with a bidirectional turret-type carousel and armless design for fast and efficient tool changes

- High Rapid Traverse Rates: Supports increased throughput and reduced cycle times

- Optional Add-ons: Available with a linear pallet changer and through-spindle coolant (CTS) for enhanced automation and cooling efficiency

| Category | Specification |

| Table | |

| Table Size | 650 × 350 mm |

| T-Slot (N × W × P) | 3 × 14 × 125 mm |

| Max. Load on Table | 400 kgf |

| Machine Capacity | |

| Travels (X / Y / Z) | 400 / 350 / 320 mm |

| Spindle Face to Table | 135 – 455 mm |

| Spindle | |

| Nose Taper | 7 / 24 No. 40 |

| Speed (Std. / Opt.) | 6000 rpm / up to 10000 rpm |

| Rapid Traverse (X/Y/Z) | 40 / 40 / 40 m/min |

| Spindle Power | |

| FANUC (0iMF+) | 5.5 / 3.7 kW (Opt. 7.5 / 5.5) |

| Mitsubishi (M80) | – |

| Siemens (828D) | 5.5 / 3.7 kW |

| ATC (Tool Changer) | |

| No. of Tools | 12 |

| Tool System | Disc Armless, BT-40 |

| Pallet Changer (Opt.) | |

| Linear Type | 500 × 325 mm (2 Pallets) |

| Rotary Type | – |

| Installation Data | |

| Width × Depth | 1.7 × 2.8 m |

| Net Machine Weight | 3300 kgf |