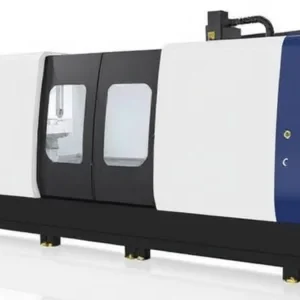

GV40

This high-performance, high-productivity drill-type machining center features a compact gantry design, engineered for speed and accuracy in demanding industrial applications. Equipped with a high-speed, high-torque BBT-30 spindle—or an optional 20,000 rpm direct-drive HSK A50 spindle—it is ideally suited for precision component machining across automotive, aerospace, and general engineering sectors.

Key features include:

- High-Speed Turntable Interface: Enables tool changeovers in just 5 seconds

- AI Servo Tuning and Feedforward Control: Enhances dynamic performance and surface finish quality

- Smart Spindle Load Monitoring: Provides real-time feedback for optimized cutting conditions and increased machine reliability

Designed for versatility and consistent output, this machining center ensures superior productivity and precision across a wide range of materials and part geometries.

| Item | Specification |

| Travels (X/Y/Z) | 500 / 400 / 400 mm |

| Spindle to Table Dist. | 160 – 560 mm |

| Table Size | 600 × 400 mm |

| Max. Table Load | 400 kg |

| Turn Table (Optional) | 760 × 400 (×2) |

| Tool Shank | BT-30 / HSK A50 |

| Spindle Speed (Std.) | 10000 / 12000 rpm |

| Spindle Speed (Opt.) | 16000 / 20000 rpm |

| Spindle Power (Std.) | 7.5 / 5.5 kW (18.5 / 15 / 11) |

| Cutting Feed | 1 – 20000 mm/min |

| Rapid Traverse (X/Y/Z) | 50 / 50 / 48 m/min |

| ATC Tools | 26 |

| Chip-to-Chip Time | 5 sec |

| Tool Changer | Direct Pick-up |

| Tool Ø / Weight Max. | 140 mm / 3 kg |

| Tool Length Max. | 300 mm |

| Accuracy / Repeat. | 0.010 mm / ±0.003 mm |

| Control System | FANUC 0iMF+ |

| Machine Weight (Net) | 6000 kgf |