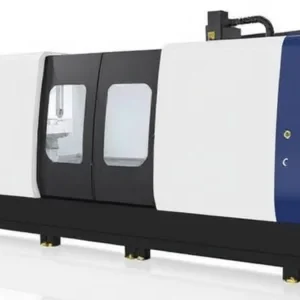

TCV-540

High-Speed Compact Machining Center with Turntable for Drill Tap and Milling Applications

This high-speed machining center with an integrated turntable is purpose-built for drill tap operations while also offering full milling capabilities. Compact yet powerful, the machine features a rigid structural design and high-speed performance that enable exceptional accuracy and productivity.

Ideally suited for machining automotive and general engineering components, it provides the flexibility and reliability required for high-efficiency production environments.

| Item | Specification |

| Travels (X/Y/Z) | 500 / 400 / 320 mm |

| Spindle to Table Distance | 200 – 520 mm |

| Table Size | 760 × 400 mm (2) |

| Max. Table Load | 200 / 250* kg |

| Table Height | 850 mm |

| Tool Shank Type | BT-30 / BBT-30 |

| Spindle Speed (Std. / Opt.) | 10000 / up to 15000 rpm |

| Spindle Power (Std.) | 7.5 / 5.5 kW |

| Cutting Feed | 1 – 10000 mm/min |

| Rapid Traverse (X/Y/Z) | 50 / 50 / 50 m/min |

| ATC Tools | 16 |

| Tool Ø / Weight Max. | 80 mm / 2.5 kg |

| Tool Length Max. | 200 mm |

| Tool Changer Type | Disc Armless |

| Chip-to-Chip Time | 1.7 / 1.5* sec |

| Accuracy / Repeatability | 0.010 mm / ±0.003 mm |

| Control System | FANUC 0iMF+ |

| Machine Weight (Net) | 4500 kg |